Gammapilot M FMG60

Radiometric Measurement

Compact transmitter for non-contact level limit detection

(including protection equipment) level, interface and density

measurement; suitable for hazardous areas

Application

• Continuous, non-contact measurement in liquids,

solids, suspensions or sludges etc.

• Applications under extreme measuring conditions,

e.g. high pressure, high temperature, corrosiveness,

toxicity, abrasion.

• All kinds of process vessels, e.g. reactors, autoclaves,

separators, acid tanks, mixers, cyclones, cupola

furnaces.

• Applications in food processing industry without

additional requirements or approvals.

• System integration via

– HART

– PROFIBUS PA

– FOUNDATION Fieldbus

• Use in safety functions for max. level limit

Your benefits

• Compact transmitter: one instrument for all measuring

tasks

• Highest availability, reliability and safety, even for

extreme process and ambient conditions

• Highest sensitivity and accuracy at lowest dose rates

(ALARA principle)

• Optimum adjustment to the respective application via

a variety of detectors:

– point detector

– rod detectors of different lengths

• Ex d, Ex e or Ex i current output for simple plant

integration

• Stainless steel housing 316L for heavy-duty

applications

• SIL2/3 approval in accordance with IEC 61508 for

max. level limit

• WHG approval

• Temperature compensation for density measurements

• Gammagraphy detection

• Easy menu-guided onsite operation via four-line plain

text display

• Easy commissioning, documentation and

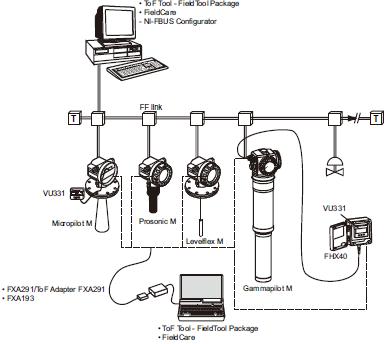

maintenance/diagnosis with operating program

(ToF Tool – Fieldtool Package or FieldCare)

Level limit detection (1)

A gamma radiation source and a Gammapilot M are mounted on opposite sides of the vessel at the height of the desired level limit. The Gammapilot M converts the received radiation intensity into a percentage. “0%” means that the radiation path is completely free, i.e. the level is below the limit. “100%” means that the radiation path is completely covered, i.e. the level is above the limit.

Continuous level measurement (2)

A gamma radiation source and a Gammapilot M are mounted on opposite sides of the vessel. The Gammapilot M calculates the level (percentage) from the radiation intensity. Detectors of different lengths are available to adapt the system to the measuring range. Also, multiple detectors can be interconnected (cascading).

Interface measurement (3)

A gamma radiation source and a Gammapilot M are mounted on opposite sides of the vessel in a height such that both liquids are irradiated. The radiation source may also be mounted inside the vessel. The Gammapilot M calculates the position of the interface layer from the intensity of the received radiation. Its value is between 0% (lowest possible position) and 100% (highest possible position).

Density or concentration measurement (4)

A gamma radiation source and a Gammapilot M are mounted on opposite sides of a measuring tube. The Gammapilot M calculates the density or concentration of the medium from the intensity of the received radiation. The unit can be freely selected. If an additional temperature sensor (5) is connected, the Gammapilot M accounts for the thermal expansion of the medium. That means, it does not output the measured density directly. Instead it calculates the density which the medium would have at a certain standard temperature defined by the user. Furthermore, the density signal of the Gammapilot M can be combined with the signal of a volume flow meter (6), e.g. Promag 55S. From these two signals it is possible to calculate the mass flow.