Description

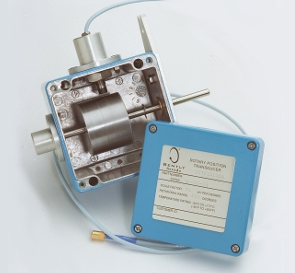

The 1900/65 General Purpose Equipment Monitor is a machinery vibration monitor designed to continuously monitor and protect equipment used in a variety of applications and industries. The low cost of the 1900/65 makes it the ideal solution for machines and processes that can benefit from continuous monitoring and protection, but cant justify thecost of traditional monitors.

Inputs

The 1900/65 provides four vibration inputs and four temperature inputs. Each vibration input is software-configurable to support 2- and 3-wire accelerometers, velocity sensors or proximity sensors. The temperature inputs support Type E, J, K and T thermocouples. Outputs Six relay outputs are available that can be programmed to open or close contacts according to user-defined logic statements operating on the OK, Alert and Danger statuses of any channel, or combination of channels. Four 4-20 mA recorder outputs are provided. Each recorder output can be software configured to output any Variable from any channel. The input signal on each vibration input is also available on a dedicated buffered output. A Modbus Gateway is available as an option, allowing the monitor to serve static variables, statuses, event list, time and date information directly to any Modbus client, including Distributed Control Systems (DCSs), Supervisory Control and Data Acquisition (SCADA) systems, Programmable Logic Controllers (PLCs) or System 1. The monitor uses an internal counter, and a time reference sent from the Modbus® client, to generate time and date. Monitors ordered without the Modbus Gateway can be upgraded by ordering the 1900/01 Communications Upgrade (see the Ordering Information section). A Modbus/TCP (Ethernet) to Modbus/RTU (serial) converter is available to support serial Modbus (see the Accessories section).

Configuration

Monitor operation and the Modbus Gateway register map are defined by creating a configuration file using software running on a laptop or PC and downloading the file to

the monitor through the built-in Ethernet connection. Configuration information is stored permanently in non-volatile memory, and can be uploaded to the PC for changes.

Display Module

The 1900/65 monitor can operate with an optional display/keypad when an application requires being able to view channel information or make minor configuration changes as a stand-alone package. If desired, the display can be mounted up to 75 meters (250 feet) from the Monitor Module.

Feature Summary

• Continuous monitoring and protection is suitable for auto-shutdown applications

• Monitor can be used for stand-alone operation or networked using Modbus/TCP communications via 10BaseT/100BaseTX Ethernet

• Small package. Monitor Module: 196.9 mm x 149.4 mm x 74.4 mm (7.75 x 5.88 x 2.93). Monitor Module with attached Display Module: 196.9 mm x 149.4 mm x 97.8 mm (7.75 x 5.88 x 3.85)

• May be DIN rail or bulkhead mounted

• Accepts 18 to 36 Vdc power. Optional 110-220 Vac external supply is available

• ۲۴-bit ADC conversion

• Four vibration/position inputs

• Four temperature inputs

• Configurable scale factors and full scale ranges

• Up to four processed variables per channel with independent integration and filter control

• Internal OK checking with status

• Independent Alert and Danger setpoints

• Event list

• Six relay outputs. Relay operation is programmable

• Buffered outputs for each transducer channel

• Four configurable 4-20 mA recorder outputs

• Optional NEMA 4X/IP68 fiberglass housing with window for display

• Painted or stainless steel weatherproof door for panel-mount display

• Hazardous area approvals